In this article, Dr. Steven Emerman, a hydrogeology expert and international mining consultant, discusses recent claims by the President of El Salvador that the country has $3 trillion in gold reserves, as well as proposals by the former Presidential Commissioner for Water to explore alternative methods to cyanide for gold extraction, such as thiosulfate, gravity processes, and bioleaching.

Using an approach that is technical and driven by global data, the viability of these claims is assessed in the context of world gold reserves and the proven effectiveness of cyanide as the predominant technology in industrial mining. The importance of basing mining-related decisions on reliable technical information is highlighted, considering both the economic opportunities and environmental challenges associated with this activity.

Introduction

In December 2024, the debate on metallic mining in El Salvador took a significant turn. President Nayib Bukele, through a series of posts on Twitter, claimed that the country has gold reserves valued at $3 trillion. These statements generated widespread public and political interest, and shortly afterward, on December 23, the Legislative Assembly approved a draft law that repeals the ban on metallic mining, in force since 2017. This change seeks to reactivate the industry under a new regulatory framework that promises a more sustainable approach.

President Bukele has emphasized that the exploitation of these reserves could transform the national economy. Meanwhile, the former Presidential Commissioner for Water, Frederick Benítez, has pointed out that it is possible to carry out extraction from ores using more sustainable and less toxic methods than cyanide, such as thiosulfate, gravitational processes, and bioleaching. These proposals have revived the debate, generating economic expectations and environmental concerns among various sectors.

This article aims to critically analyze the claims made about gold reserves and alternatives to the use of cyanide, assessing their technical feasibility and potential implications for the country. Is it possible for El Salvador to possess $3 trillion in gold reserves? Are the proposed alternatives to cyanide viable for modern industrial mining?

The analysis addresses three key issues: the plausibility of claims about gold reserves, the feasibility of alternative technologies to cyanide, and the social and environmental implications of a possible return to metallic mining. To facilitate understanding of these issues, a review of the importance of cyanide in gold extraction processes is included, as well as an analysis of the possible alternatives.

Global Context for Gold Production: Key Facts About the World and El Salvador

Is it possible that El Salvador has $3 trillion in gold reserves?

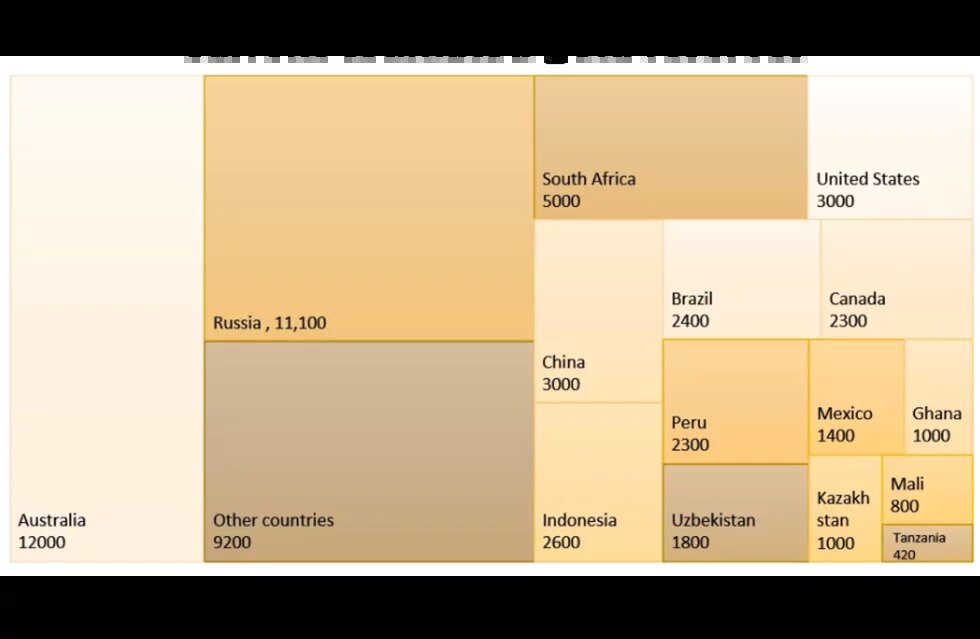

Globally, current gold reserves are estimated at approximately 59,000 metric tons, according to the U.S. Geological Survey1. According to the World Gold Council, since the beginning of its exploitation, 212,582 metric tons of gold have been extracted, representing 78% of the known mineable gold on Earth. The World Gold Council (WGC), an international organization representing the major gold mining companies, plays a key role in this global analysis. Its work includes collecting reliable data, developing technical standards, and monitoring trends in gold production. WGC estimates are essential to assess claims such as those made by the Salvadoran government, providing a technical and comparative framework for the analysis.

With an average price of $2,616.59 per troy ounce at the end of 20242,the total value of the world's gold reserves amounts to $4.96 trillion. President Nayib Bukele has stated that El Salvador potentially has gold reserves valued at $3 trillion and that the exploitation of these resources could transform the national economyl3. Based on the data presented above, this value would be equivalent to 60% of the global total of gold on the planet. Considering that El Salvador represents only 0.014% of the global continental surface, such a statement is inconsistent with the data available to date at the international level.

The estimate of the potential gold reserve, valued at $3 trillion, is based on President Bukele's statement that "studies carried out in only 4% of the potential area identified 50 million ounces of gold, valued today at $131,565 million.4" These 50 million ounces are equivalent to 1555 metric tons of gold, which would represent approximately 2.64% of the known gold reserves in the world. If we carry out a comparative exercise, 4% of the area of El Salvador (841.64 km²) would contain more gold than all of Mexico, an area that is 2,333.5 times larger and is estimated to have reserves close to 1400 metric tons.

Finally, it is important to consider the historical gold production in El Salvador, which also reinforces these discrepancies. Prior to the ban on metallic mining in 2017, national gold production was limited. In 1997, the country produced 110 kilograms of gold, a figure that decreased to 71 kilograms in 19995.Since then, no new extractions have been recorded. To put this into perspective, 1999 production represented only 0.000276% of the world production for that year 6. Even the historic San Sebastian Mine, recognized as the most productive gold mine, produced a total of 1,136,000 ounces of gold (35.33 metric tons) between 1904 and 1953. These data also contradict the claim that El Salvador may have the highest density of gold deposits per square kilometer in the world. This underlines the need for an independent and thorough analysis before drawing conclusions about the mining potential of the territory.

Are There Viable Alternatives to Cyanide in Modern Industrial Gold Mining?

The viability of metallic mining in El Salvador depends not only on the amount of gold reserves available, but also on the technologies employed for its extraction. Gold extraction has traditionally relied on cyanide, a highly effective substance, but one with significant environmental impacts. In response to these concerns, alternative methodologies have been proposed, including the use of thiosulfate, gravitational processes, and bioleaching, which promise to be less harmful to the environment. However, it is essential to assess the effectiveness, cost, and scalability of these technologies within the Salvadoran context.

Review of Cyanide

Cyanide was first used as an extractant for gold in 1889 at the Crown mine in New Zealand7. Cyanide is such an effective extractant (also called a lixiviant) that it can extract microscopic quantities of gold from a large body of gold ore, on the order of fractions of a gram of gold per metric ton of ore (fractions of a part per million). In this way, the gold mining industry has continued to be profitable, even while the grades of the remaining gold deposits have declined from 50 grams per metric ton in the mid-19th century to less than 1 gram per metric ton at the present time 8. According to Laitos (2013)9, “Nonetheless, by the 21st century, over 90% of gold extracted worldwide is the result of cyanide leaching techniques. Prior to the introduction of cyanide leaching operations, most low-grade ore deposits could not be profitably removed using traditional placer or lode mining techniques; to that end, the low capital costs associated with cyanide heap leaching have made profitability on low-grade ores a reality. By utilizing cyanide mineral leaching techniques in large-tonnage mine projects, operators were able to extract small, sometimes microscopic flecks of gold and other precious minerals from low-grade ore with 90% to 95% efficiency”.

According to the U.S. Geological Survey, “Cyanidation is applied at one stage or another to the recovery of nearly all gold extracted from precious metal ores … The environmental concerns about ore processing center around the universal use of cyanide, which is a lethal poison, to extract gold from its ores.” 10

Cyanide is highly toxic and can be lethal to birds, wildlife, aquatic organisms, livestock, and humans if it is accidentally released into the environment. The lethal effect of cyanide results from its tendency to attach to red blood cells, so that the blood cells can no longer release oxygen to tissues and organs, resulting in suffocation. Because of its high toxicity, alternatives to cyanide have been sought for over a century, or almost since the use of cyanide in gold ore processing was first introduced.

Any alternative lixiviant to cyanide should have some combination of the following characteristics11:

- It should be relatively inexpensive.

- It should be selective, meaning that it preferentially extracts gold and not every other metal.

- It should be relatively easy to separate the dissolved gold from the lixiviant.

- It should be relatively recyclable, meaning that after extracting gold from gold ore, the lixiviant can be recovered, so that it can be applied to more gold ore.

- It should be relatively non-toxic.

- It should be possible to destroy or recover the lixiviant from any water or waste that might be released into the environment.

After over a century of research, no lixiviant has emerged that satisfies a reasonable number of the above characteristics.

Mercury is just as effective at extracting gold as cyanide, but it is much more toxic and is highly persistent in the environment. On that basis, the World Gold Councill12 does not recommend the use of mercury for gold processing under any circumstances.

Thiosulfate is an effective lixiviant and less toxic than cyanide, but it is usually too expensive due to its high consumption rate during gold ore processing, in addition to the complexity of separating the gold from the lixiviant13. According to Barrick Gold14, “Thiosulfate is infamous in chemistry circles for yielding varying results if not managed exactly right. In gold mining terms, failing to get it right means that gold recovery rates can be unpredictable and thiosulfate consumption can be very high, pushing up costs.”

Coal-gold agglomeration (CGA) is far less toxic than cyanide, but is effective only for extracting free gold particles (such as may be found in river or beach deposits), not in extracting gold from hardrock15.

In summary, despite its toxicity, the modern gold mining industry could not exist in its present form without the use of cyanide.

The process of gold ore processing using cyanide involves dissolving a cyanide salt (such as sodium cyanide) in water, so that it dissociates to form the cyanide ion (CN–) and hydrogen cyanide (HCN). The gold ore is crushed and is either placed onto a heap leach pad, where cyanide solution is poured over it, or mixed with the cyanide solution in a vat. The cyanide ion extracts the gold from the ore to form a dissolved gold-cyanide complex. The solution with the gold-cyanide complex is called the pregnant solution. There are two important processes for removing the gold-cyanide complex from the pregnant solution. In the first process, the pregnant solution is mixed with or passed over activated carbon, so that the gold-cyanide complex leaves the solution and attaches to the activated carbon, after which the solution is referred to as the barren solution. Further steps (called stripping or elution) remove the gold from the activated carbon and restore the cyanide to the barren solution. Any lost cyanide is replaced in the barren solution and the solution is then recycled to extract additional gold from more gold ore. The second important process is called zinc cementation or the Merrill-Crowe process. In this process, the addition of zinc dust to the pregnant solution creates a highly-reducing (low-oxygen) environment. The highly-reducing environment causes gold to be reduced to its elemental (metallic) state, so that it precipitates as solid particles of gold. As with the activated carbon process, any lost cyanide is replaced in the barren solution and the solution is then recycled to extract additional gold from more gold ore16.

Thiosulfate is not a Viable Alternative to Cyanide

The only mine in the world that uses thiosulfate for gold extraction is the Barrick Gold Goldstrike mine in Nevada (USA). According to Barrick Gold17, “The new circuit uses thiosulfate, a chemical reagent, to treat double-refractory ore that cannot be treated using conventional processes”. A double-refractory ore presents two challenges for cyanide extraction. First, the gold particles are encapsulated within sulfide minerals, so that cyanide cannot react with gold unless the sulfide minerals are oxidized. Second, the ore contains organic carbonaceous material that can absorb the gold-cyanide complex, thus preventing recovery of both the gold and the cyanide. In other words, Barrick Gold decided to use thiosulfate at this particular mine only because cyanide extraction was completely unworkable and the only alternative would have been to abandon gold production. No other mine in the world has come to the same decision simply because of the high cost and operational complexity of thiosulfate extraction.

Gravitational Methods are not a Viable Alternative to Cyanide

Gold deposits from which the gold could be extracted using only gravitational methods were largely exhausted by the Roman period and certainly by the 16th century, which was the motivation by inventing the process of amalgamation with mercury around 100 BC and its widespread use in the New World during the Colonial Period. There are no mines in the world today that use gravitational methods for gold extraction, except as a pre-treatment to produce a gold concentrate prior to the use of chemical reagents. Thus, the reliance on gravitational methods is confined to the culture of recreational or “hobby” gold miners. In any event, like coal-gold agglomeration (CGA), gravitational methods can be used only to separate free gold particles from unconsolidated beach and stream deposits, not in the extraction of gold from hardrock.

Even artisanal gold miners cannot rely on gravitational methods alone. According to Veiga and Gunson (2020)18, “Once the gold is concentrated into a small mass, the challenge is to extract gold from these concentrates … In the large majority of AGM [Artisanal Gold Mining] operations, gold from gravity concentrates or high-grade ores is amalgamated. In the past, many researchers and international agencies promoted the amalgamation of only gravity concentrates, instead of whole ore amalgamation, as the best way to reduce mercury losses. Even without success of reducing mercury use, nowadays all efforts from projects aim at the complete elimination of mercury in AGM by using only gravity concentration; however, this is not practical for the miners if they do not have an affordable and simple method to extract gold from the concentrates. Amalgamating gravity concentrations can reduce drastically the use and loss of mercury, but mercury use cannot be eliminated unless an alternative, such as a leaching process, is used to extract gold from concentrates”.

Bioleaching is not a Viable Alternative to Cyanide

There are no mines that use bioleaching (also called bio-oxidation) as a replacement for cyanide in gold extraction. Bioleaching is only a pre-treatment step in that micro-organisms are used to oxidize the sulfide minerals prior to the application of cyanide. According to Roberto and Schippers 19,“While base metals may be dissolved in solution through biological action of iron and sulfur-oxidizing microorganisms … gold remains insoluble until a suitable lixiviant (typically cyanide) is applied to biooxidized ore or concentrate residues. The role of the microbes in the case of gold is to liberate gold from sulfidic mineral matrices like arsenopyrite to increase the access of the gold lixiviant.” As of 2022, there were 15 operating gold mines that used bioleaching as a pre-treatment step, accounting for 1.9% of world gold production.

Conclusions

Based on the analysis, the following conclusions can be drawn:

-

Viability of claims regarding gold reserves:

The claim that El Salvador has $3 trillion in gold reserves is not supported by the available global data. Currently, global gold reserves are estimated at less than $5 trillion. The proportion attributed to El Salvador represents 60% of the world total, which is inconsistent, especially considering the country's limited surface area and its historical gold production.

-

Use of cyanide in industrial gold mining:

Although cyanide is a highly toxic substance, it remains the predominant technology in industrial gold mining due to its effectiveness and relatively low cost. Proposed alternatives, such as thiosulfate and bioleaching, have significant limitations in terms of cost, efficiency and scalability. Currently, none of these alternatives are viable for replacing cyanide on a large scale.

-

Importance of reliable data in decision-making:

The recent lifting of the ban on metallic mining underlines the importance of decisions based on solid and verifiable technical data. Assessing the economic, environmental and social implications of mining requires independent studies, transparent analysis, and robust regulatory frameworks to avoid long-term risks.

In conclusion, any decision related to metallic mining in El Salvador must be based on technical evidence, prioritizing environmental sustainability and the well-being of local communities.

Footnotes

- 1

World Gold Council, 2024b. Above-ground Stock.

- 2

World GoldCouncil, 2024a. The Global Experts on Gold.

- 3

Bukele, N., 2024a. Dios Colocó un Gigantesco Tesoro bajo Nuestros Pies [God Placed a Gigantic Treasure under Our Feet]: X Post, November 27, 2024.

- 4

- 5

USGS (U.S. Geological Survey), 2001. Gold – Minerals Yearbook – 2001, 14 p. Available online at: https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/mineral-pubs/gold/goldmyb01.pdf

USGS (U.S. Geological Survey), 2002. Gold – Minerals Yearbook – 2002, 14 p. Available online at: https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/mineral-pubs/gold/goldmyb02.pdf

USGS (U.S. Geological Survey), 2003. Gold – Minerals Yearbook – 2003, 13 p. Available online at: https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/mineral-pubs/gold/gold_myb03.pdf - 6

USGS (U.S. Geological Survey), 2003.

- 7

Johnson, C.A., 2015. The fate of cyanide in leach wastes—An environmental perspective: Applied Geochemistry, vol. 57, pp. 194-205.

- 8

Mudd, G.M., 2010. The environmental sustainability of mining in Australia—Key mega-trends and looming constraints: Resources Policy, vol. 35, pp. 98-115.

- 9

Laitos, J.G., 2013. Cyanide, mining, and the environment: Pace Environmental Law Review, vol. 30, pp. 869-949.

- 10

USGS (U.S. Geological Survey), 2005. Mineral Commodity Profiles – Gold, 72 p.

- 11

Laitos, J.G., 2013.

- 12

World Gold Council, 2019. Responsible Gold Mining Principles: September 2019, 19 p.

- 13

Xu, B., W. Kong, Q. Li, Y. Yang, T. Jiang, and X. Liu, 2017. A review of thiosulfate leaching of gold—Focus on thiosulfate consumption and gold recovery from pregnant solution: Metals, vol. 7, 16 p.

- 14

Barrick Gold, 2016. Processing Innovation Nets Metallurgy Award—First time any company in the western world produces gold on a commercial scale using thiosulfate: October 6, 2016.

- 15

Laitos, J.G., 2013.

- 16

Botz, M.M., 2024. Basic cyanide chemistry—An essential guide for gold and silver leaching: Society for Mining, Metallurgy and Exploration, Englewood, Colorado, 112 p.

- 17

Barrick Gold, 2016.

- 18

Veiga, M.M. and A.J. Gunson, 2020. Gravity concentration in artisanal gold mining: Minerals, v. 10, 49 p.

- 19

Roberto, F.F. and A. Schippers, 2022. Progress in bioleaching—Part B, applications of microbial processes by the minerals industries: Applied Microbiology and Biotechnology, v. 106, pp. 5913-5928.